Stepper Servo · 17 Years of Expertise

Application

Application of Communication Servo in Automatic Slitting Machine

Abstract: The strip cutting machine is an essential choice for cutting bundled strips and (rolled) strips in industries such as shoemaking, clothing, luggage, hats, garment accessories, medical supplies, reflective materials factories, tent factories, umbrella factories, gift packaging, flag making, and decorative accessories.

1. Equipment Introduction

The strip cutting machine is an essential choice for cutting bundled strips and (rolled) strips in industries such as shoemaking, clothing, luggage, hats, garment accessories, medical supplies, reflective materials factories, tent factories, umbrella factories, gift packaging, flag making, and decorative accessories.

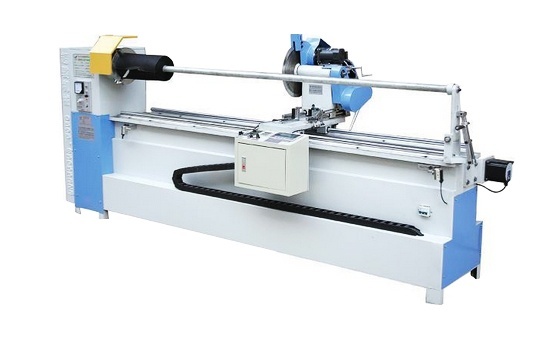

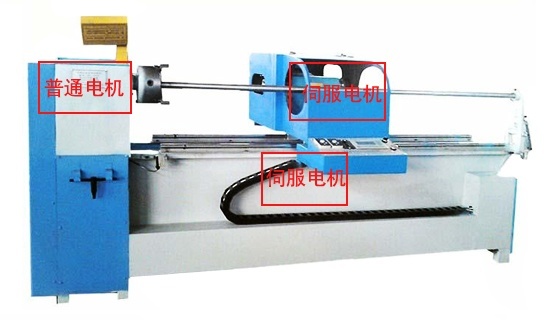

2. Equipment Image and Hardware Configuration

The image below shows the strip cutting machine equipment, which consists of one ordinary motor and two servo motors controlling the entire operation of the device.

3. Equipment Configuration

This equipment configuration includes B1Z-24MT, MD204LV, and two Lichuan servos as shown in the figure below.

4. Equipment Process

• 1. Cutting fabric by moving a fixed length from the origin point.

• 2. Positioning accuracy of 0.1mm.

• 3. Automatic return to origin after a certain number of positioning cycles.

• 4. Frequency converter controls the spindle speed.

5. Equipment Functions Completed

1. The spindle and circular knife use a variable frequency speed control system, allowing stepless speed regulation and forward/reverse switching control.

2. The cutting width accuracy reaches 0.1mm, with the narrowest cutting width being 2mm. During cutting, the feed moves parallel and quickly, with stepless speed regulation and segmented control. The paper tube is easily cut, achieving high precision and fast production of high-quality products.

3. The operation interface uses an LCD Chinese display screen, providing a visual human-machine interface that saves time and is simple and clear to operate. Multiple cutting widths and quantities can be directly set, with optional manual/automatic switching functions, making it usable by ordinary workers.

Shenzhen Lichuan Electric Co., Ltd.

Technical Support

Engineer Peng:+86-135-3098-8140

Engineer Xie:86-159-0755-7836

Engineer Rao:86-180-2520-1553

Engineer Zuo:86-180-2901-2526

WeChat Public Account

Douyin ID

Official Website Mobile Version

Sorry,当前栏目暂无内容!

您可以查看其他栏目或返回 首页

Sorry,The current column has no content!

You can view other columns or return Home

WeChat

WeChat