Stepper Servo · 17 Years of Expertise

Application

Application of Communication Servo in Automatic Tapping Machines

Abstract: The tapping machine is a commonly used device in mechanical processing. Traditionally, tapping machines were mostly operated manually, resulting in low efficiency and poor precision, which cannot meet the needs of modern high-efficiency production. There is an urgent need for a high-efficiency, high-precision automatic tapping technology.

The tapping machine is a commonly used device in mechanical processing. Traditionally, tapping machines were mostly operated manually, resulting in low efficiency and poor precision, which cannot meet the needs of modern high-efficiency production. There is an urgent need for a high-efficiency, high-precision automatic tapping technology. An automatic tapping machine control system was developed using Lichuan servo system, touch screen, and other components. After debugging, it has been put into use. The entire system features high efficiency, high precision, and strong reliability. The working principle of the automatic tapping machine involves setting tapping parameters such as thread depth, pitch, and speed on the touch screen.

I. Requirements for Electric Tapping Machine

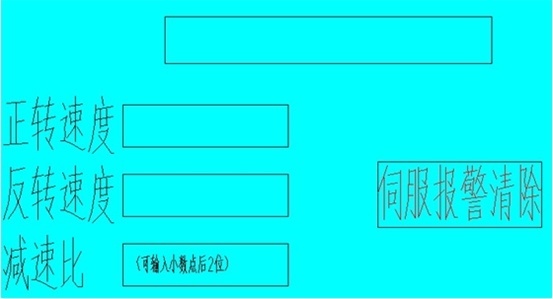

The interface has three working modes: free mode, fixed circle mode, and depth mode. The machine starts in free mode screen, and returning goes to the mode selection screen. The control handle has two buttons, red and green, used as direction switches, and a small button used as a limit switch.

1. In free mode:

① Motor speed = forward speed (or reverse speed) × reduction ratio

② Hold the green switch for motor forward rotation; hold both green and red switches for motor reverse rotation (pressing the red switch alone has no effect).

③ During forward rotation, the upper box on the screen displays "Free Mode Forward"; during reverse rotation, it displays "Free Mode Reverse"; any abnormalities show a servo alarm.

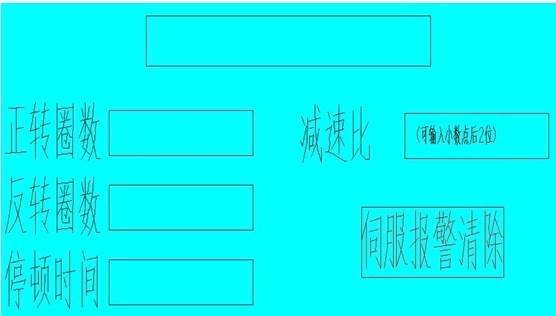

II. In fixed circle mode:

① Motor rotation count = forward rotation count (or reverse rotation count) × reduction ratio.

② Hold the red switch to automatically perform tapping in fixed circle mode (tapping completes and exits after the set number of rotations). Releasing the red switch during tapping stops the process.

③ During forward rotation, the upper box on the screen displays "Fixed Circle Mode Forward"; during reverse rotation, it displays "Fixed Circle Mode Reverse"; any abnormalities show a servo alarm.

④ Pause time input is in milliseconds.

III. In depth mode (this mode is programmed but not yet available on the display):

① Hold the green switch for motor forward rotation; press the limit switch once for motor reverse rotation; release the green switch to stop the motor.

IV. If the motor encounters an abnormal condition, a servo alarm is displayed, which can be cleared on the screen.

V. The main interface of the touch screen is as follows:

VI. First, set the tapping depth, thread settings, tapping speed, and reverse speed (tapping speed set as positive, reverse speed set as negative), then press the reduction ratio button to enter the reduction ratio setting interface as follows:

1. Set the reduction ratio of the reducer you selected here, then press the return key.

2. In manual mode, pressing the left and right buttons on the handle will rotate the motor at the set tapping/reverse speed.

3. In automatic mode, pressing the trigger button on the handle will cause the motor to automatically perform one tapping and reverse operation according to the set tapping depth.

Shenzhen Lichuan Electric Co., Ltd.

Technical Support

Engineer Peng:+86-135-3098-8140

Engineer Xie:86-159-0755-7836

Engineer Rao:86-180-2520-1553

Engineer Zuo:86-180-2901-2526

WeChat Public Account

Douyin ID

Official Website Mobile Version

Sorry,当前栏目暂无内容!

您可以查看其他栏目或返回 首页

Sorry,The current column has no content!

You can view other columns or return Home

WeChat

WeChat