Stepper Servo · 17 Years of Expertise

Application

Application of servo drivers and motors in one-to-two flat mask machines

The high-speed fully automatic one-to-two flat mask production line is a fully automatic high-speed flat earband mask production line, including automatic raw material feeding, automatic conveying, nose bridge strip cutting, mask edge welding, folding, ultrasonic fusion, forming, cutting, and other fully automated processes, completing the entire production process from roll raw materials to finished masks.

1. Methods and Steps

1. The high-speed fully automatic one-to-two flat mask production line consists of a main machine and an earband machine connected together. After the main machine outputs the mask body, the conveyor structure transports the mask body sheet to the flipping mechanism, which flips the mask tray onto the conveyor connected to the earband machine. Then, the conveyor transports the mask sheet above the first mask tray of the earband machine. Finally, a cylinder presses down to place the mask sheet into the earband machine's mask tray. The earband machine then completes the earband welding, edge wrapping, and other actions to produce a finished earband mask product.

2. The high-speed fully automatic one-to-two flat mask production line is mainly used for automatic forming of flat masks: after unrolling the entire roll of fabric driven by rollers, the fabric undergoes automatic folding and edge wrapping; the entire roll of nose bridge strips is pulled and unrolled, cut to a fixed length, and fed into the edge-wrapped fabric. Both sides are ultrasonically welded to seal the edges, then ultrasonically sealed laterally, and cut into shape by a cutter. The masks are conveyed via the assembly line to two mask earband welding stations, where ultrasonic welding completes the final mask forming. After the masks are made, they are conveyed to a flat belt line for collection.

3. Production Line Features:

1. The entire equipment is fully automated.

2. High stability, low failure rate, aesthetically pleasing, sturdy, and rust-resistant.

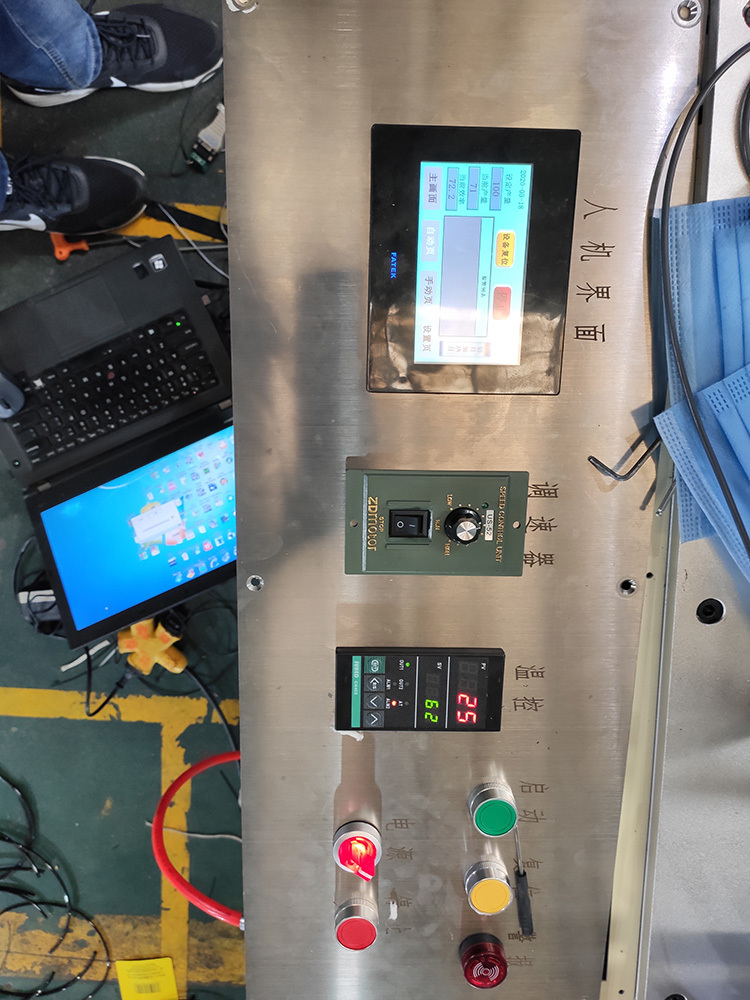

3. Computer PLC programming control, servo drive, high degree of automation.

4. Automatic raw material tension control to ensure balanced raw material tension.

5. Photoelectric (fiber optic) detection of raw materials to avoid errors and reduce waste.

4. Mechanical Features:

1. Automatic raw material tension control to ensure balanced raw material tension.

2. Photoelectric detection of raw materials to avoid errors and reduce waste.

3. Capable of producing mask bodies with one to four layers; the flat length on the finished product conveyor is 1200MM.

4. The machine has total count and batch count functions; the batch count quantity can be set arbitrarily.

5. Changing molds allows production of masks of different sizes and styles.

6. The entire machine uses aluminum alloy structure, which is aesthetically pleasing, sturdy, and rust-resistant.

Adjustable mechanical parts: the folding section can be adjusted; mask body welding points can be designed; the machine can produce masks with 1-4 layers of fabric (activated carbon material can be added in the middle).

Lichuan Servo System Advantages

Figure 5 Parameter Setting Interface

(1) Precise positioning and high response of the servo can quickly adapt to the engraving machine's requirements for high precision and wide frequency response.

(2) The servo's overload capacity and high-speed torque holding characteristics can meet the engraving machine's load variation requirements.

(3) User-friendly human-machine interface; Figure 5 shows the parameter setting interface. Servo communication allows quick modification of setting parameters and tracking of speed change curves.

(4) When resonance, noise, vibration, or limited response occurs, mechanical resonance can be eliminated by setting software filters, improving machine tool responsiveness.

(5) The servo system has excellent low-speed characteristics and extremely high speed response.

Conclusion

The application of the Lichuan series servo system in mask machines is of great significance for breakthroughs in automation system technology in this industry. The project plays a very positive role in the high-end application of domestic brand servo systems in the mask machine field.

Shenzhen Lichuan Electric Co., Ltd.

Technical Support

Engineer Peng:+86-135-3098-8140

Engineer Xie:86-159-0755-7836

Engineer Rao:86-180-2520-1553

Engineer Zuo:86-180-2901-2526

WeChat Public Account

Douyin ID

Official Website Mobile Version

Sorry,当前栏目暂无内容!

您可以查看其他栏目或返回 首页

Sorry,The current column has no content!

You can view other columns or return Home

WeChat

WeChat