Stepper Servo · 17 Years of Expertise

Application

Application of Servo Motors in the Engraving Machine Industry

Application of Servo Motors in the Engraving Machine Industry

Introduction

Previously, the production of various models relied entirely on manual cutting and bonding, which involved high labor intensity, long time consumption, and low production accuracy. Now, whether it is intricate Chinese-style doors and windows, decorative railings, or modern skyscrapers, engraving machines make processing easy and fast, and the production results are more delicate and beautiful. It can be said that advanced productivity has created all of this.

Simple Process

A computer engraving machine consists of three parts: a computer, an engraving machine controller, and the engraving machine host. Its working principle is: design and layout are done through specialized engraving software configured in the computer, and the computer automatically transmits the design and layout information to the engraving machine controller. The controller then converts this information into power signals (pulse trains) that drive the servo motor, controlling the engraving machine host to generate the X, Y, and Z axis engraving tool paths. Meanwhile, the high-speed rotating engraving head on the engraving machine uses tools configured according to the processing material to cut the material fixed on the host workbench, achieving automated engraving operations. Figure 1 shows the appearance of a CNC engraving machine.

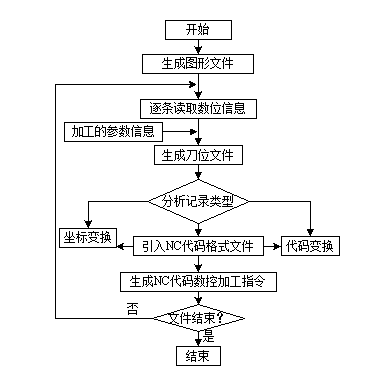

Figure 2 shows the workflow diagram of the engraving machine. The graphic input part processes and organizes the graphics to be engraved through engraving software into digital graphic files recognizable by the computer, enabling automatic control of the processing machinery. Next is the data processing part, where the computer further processes the graphic files from the engraving software into electrical signals that control the machinery's movements. Then comes the automatic control of the processing procedure, where the engraving machine executes computer instructions to complete the graphic engraving. Throughout the process, the operator is only responsible for inputting processing data, loading and unloading workpieces, and monitoring the process; all other tasks are automatically completed by the engraving machine equipment, making it very simple and labor-saving.

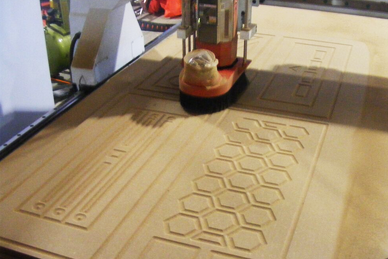

Figure 1 Appearance of CNC Engraving Machine

Figure 2 Workflow Diagram of CNC Engraving Machine

Overview of Engraving Machines

Computer engraving machines are divided into laser engraving and mechanical engraving types, each with high-power and low-power versions. Because the application range of engraving machines is very broad, it is necessary to understand the most suitable application areas for various engraving machines. This article mainly introduces woodworking engraving machines and mold engraving machines.

Computer engraving machines are divided into laser engraving and mechanical engraving types, each with high-power and low-power versions. Because the application range of engraving machines is very broad, it is necessary to understand the most suitable application areas for various engraving machines. This article mainly introduces woodworking engraving machines and mold engraving machines. Currently, most woodworking engraving machines used by furniture manufacturers still use stepper motor systems. Due to the low speed and large step angle of stepper motors, the engraving speed is slow and the engraving accuracy is poor, directly affecting the production efficiency and quality of furniture factories. Moreover, stepper motor systems are prone to missed steps and cannot correct errors in time, causing material loss. AC servo systems, as high-speed and high-resolution motion control systems, have unparalleled advantages here and help improve the stability of the engraving machine system, greatly enhancing the overall performance of the engraving machine.

Typically, stepper motors have a full step angle of 1.8 degrees and a half step of 0.9 degrees, so the resolution per revolution is 360/0.9=400. Under effective output power conditions, the maximum speed is 600 RPM. If the motor is not changed but higher precision is required, there are two methods: one is to reduce the lead of the screw per revolution; the other is to transmit the motor power to the screw through a reduction gear. Both methods come at the cost of reduced processing speed. Obviously, reducing speed contradicts production efficiency. To completely solve the contradiction between speed and precision, only a faster, higher-resolution, and smoothly operating AC servo system can be used.

The motor can reach speeds of 3000 RPM under constant torque output, with an encoder line count of 2500 PPR. The driver uses 4x frequency multiplication technology to subdivide control pulses by 4, achieving a motor resolution of 10000 PPR per revolution. Clearly, both its speed and precision far exceed the requirements of woodworking engraving machines.

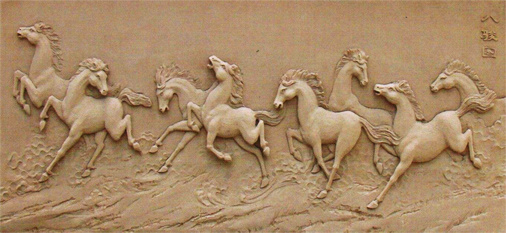

Mold engraving machines are mainly used for processing and producing various advertising crystal letters, signs, badges, department plates, architectural models, rulers, small metal and wooden molds, stone engraving, furniture making, and reliefs.

Mold engraving machines require fast servo response speed and high positioning accuracy. Therefore, improving the servo system's response bandwidth and encoder resolution are the main indicators for enhancing mold engraving machine performance.

Below is a sample of engraving machines:

Figure 2 Woodworking Engraving Sample

Equipment Composition

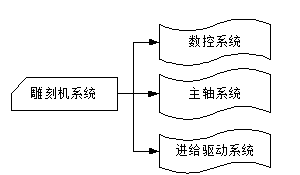

A computer engraving machine consists of three parts: a computer, an engraving machine controller, and the engraving machine host.

Figure 4 Engraving Machine System

CNC System: Uses a CNC system developed by the customer.

Spindle System: Uses an integrated electric spindle driven by a frequency converter.

Feed Drive System: Ball screw, elastic coupling, linear guide rail, servo drive system.

Advantages of Lichuan Servo System

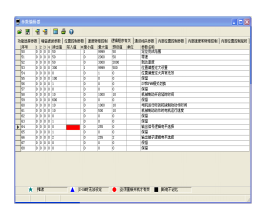

Figure 5 Parameter Setting Interface

(1) The servo provides precise positioning and high responsiveness, quickly adapting to the engraving machine's requirements for high precision and wide frequency response.

(2) The servo's overload capacity and high-speed torque holding characteristics can adapt to the engraving machine's load changes.

(3) User-friendly human-machine interface; Figure 5 shows the parameter setting interface. Servo communication allows quick modification of setting parameters and tracking of speed change curves.

(4) When resonance, noise, vibration, or response limitations occur, mechanical resonance can be eliminated through software filter settings, improving machine tool responsiveness.

(5) The servo system has excellent low-speed characteristics and very high speed responsiveness.

Conclusion

The application of the Lichuan B3 series servo system in engraving machines is of great significance for breakthroughs in domestic electromechanical automation system technology in this industry. The project plays a very positive role in the high-end application of domestic brand servo systems in the CNC engraving machine field.

Shenzhen Lichuan Electric Co., Ltd.

Technical Support

Engineer Peng:+86-135-3098-8140

Engineer Xie:86-159-0755-7836

Engineer Rao:86-180-2520-1553

Engineer Zuo:86-180-2901-2526

WeChat Public Account

Douyin ID

Official Website Mobile Version

Sorry,当前栏目暂无内容!

您可以查看其他栏目或返回 首页

Sorry,The current column has no content!

You can view other columns or return Home

WeChat

WeChat