Application of Servo Communication System in Heat Sealing and Cutting Bag Making Machine

Abstract: Lichuan Company has launched a dedicated servo control solution for the current domestic heat sealing and cutting bag making machines, which has been successfully applied in the domestic bag making equipment industry. This solution uses Lichuan B series AC synchronous servo drivers, 130 series AC permanent magnet synchronous servo motors, touch screens, PLCs, frequency converters, frequency motors, and other main components;

1. Introduction

Lichuan Company has launched a dedicated servo control solution for the current domestic heat sealing and cutting bag making machines, which has been successfully applied in the domestic bag making equipment industry. This solution uses Lichuan B series AC synchronous servo drivers, 130 series AC permanent magnet synchronous servo motors, touch screens, PLCs, frequency converters, frequency motors, and other main components. According to the equipment process requirements, the 130 series servo motor with medium inertia and high speed was selected as the main motion mechanism, ensuring the stability and rapid response of the sealing and cutting bag machine under frequent start-load conditions. This allows the servo motor's primary feeding speed to meet the time requirements for the cutter's up and down movement. At the same time, the mechanical structure was simplified, solving the problems of low efficiency, low positioning accuracy, high energy consumption, low automation level, and material waste in the original mechanical equipment.

2. Control Principle

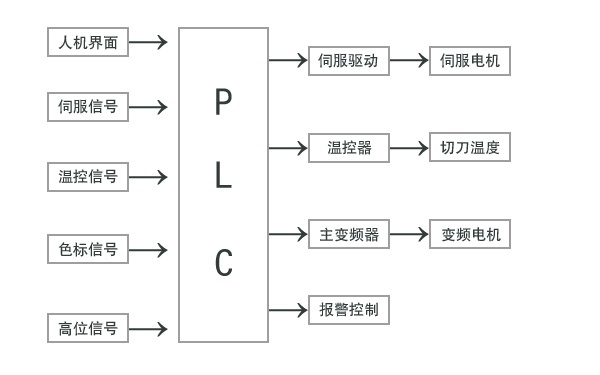

The entire equipment production process is mainly divided into three parts: lifting the knife, positioning, and sealing and cutting. The up-and-down reciprocating movement of the heat sealing knife and cutting knife is controlled by a frequency converter driving a frequency motor. The bag length positioning is controlled by a servo driver controlling a servo motor that drives the feeding roller. Additionally, photoelectric sensors (also called photo eyes), temperature controllers, and proximity switches serve as measurement and control components responsible for timing judgment and issuing control signals, establishing timing relationships among actuators. The PLC acts as the core program carrier, responsible for sending pulse signals and converting and transmitting various control signals, ultimately controlling the operation and coordination of each actuator. The touch screen serves as the human-machine interface for parameter setting and monitoring the entire machine's operating status. Through the touch screen, operations such as adjusting bag length, zeroing, resetting, and jogging can be performed; it can also display the bag length value and the cumulative number of processed bags.

The following diagram is the control principle block diagram of the heat sealing and cutting machine:

3. Workflow

1. System Power On

Program initialization, input bag length value, adjust the temperature controller to make the sealing knife temperature meet the heat sealing requirements (the sealing knife temperature should be set according to the main motor speed, ensuring the bag seal is firm and durable. If the sealing knife temperature is too low, the bag seal will be weak. If the temperature is too high, the bag seal may be burnt through. Therefore, adjust according to the main motor speed and sealing time); enter manual adjustment mode, check whether the mechanical parts, servo system, frequency converter, etc., can work normally, and adjust the color mark photoelectric eye to sense color mark changes.

2. Bag Making

Click the automatic run button on the touch screen, the main frequency motor (1.5KW) operates, driving the sealing knife and cutting knife to move up and down through mechanical linkages. Each time the cutting knife moves up once, the servo signal is activated once. The PLC sends pulses to control the servo motor (1.5KW) operation. The number of pulses determines the number of rotations of the servo motor, and the pulse frequency determines the servo motor speed. The servo motor drives the feeding roller via a synchronous belt to feed material. The servo motor must complete positioning before the cutting knife descends to the cutting roller. After the cutting knife and sealing knife cut down, the bag is formed. When the number of cut bags reaches the preset number or the emergency stop button is pressed, the machine stops after finishing the current bag, and the cutting and sealing knives stop at the high position parking area.

The bag making machine generally has two sealing and cutting methods: blank bag fixed-length sealing and cutting, and mark-seeking sealing and cutting. When selecting blank bag fixed-length sealing and cutting, the color mark photoelectric eye does not function. The PLC program calculates the number of pulses required for servo system positioning based on the bag cutting length, mechanical transmission ratio, electronic gear ratio of the servo driver, encoder line count of the servo motor, and circumference of the feeding roller. Then the driver drives the servo motor to rotate the feeding roller to feed a certain length of bag, achieving fixed-length sealing and cutting of blank bags. When selecting mark-seeking sealing and cutting, the process is as follows: the servo start signal is activated, and the servo motor accelerates, runs at constant speed, decelerates, and performs low-speed mark tracking according to the motion curve preset in the PLC program, as shown in Figure 3. When the PLC receives the mark tracking signal, it immediately stops the servo motor via interrupt. Generally, the mark tracking length is 10mm, and the mark tracking signal should only be effective within the tracking range; interference signals outside this range must be shielded. During mark tracking sealing and cutting debugging, set the servo motor's constant speed on the human-machine interface, first set long acceleration and deceleration times, then adjust the low-speed mark tracking speed, trying to increase it as much as possible for smooth and accurate tracking. After adjusting the tracking speed, shorten acceleration and deceleration times as much as possible to prevent relative slip between the bag and the feeding roller and ensure smooth tracking. During mark tracking sealing and cutting, the PLC program counts the tracking signals; if no signal is detected three consecutive times, the PLC stops all motors and triggers an alarm. The PLC program also counts batches; when the batch reaches a warning value, the PLC triggers an alarm to prompt the operator.

Mark Tracking Speed Curve Diagram

4. Servo System Introduction

The servo system used in this machine adopts the latest digital signal processor (DSP) from TI, USA, as the core of the drive unit, and selects Mitsubishi's industrial-grade intelligent power module (IPM). The chosen IPM has a capacity one level higher than other domestic servo products of the same rated power, thus featuring strong overload capacity, strong load disturbance resistance, high starting torque, and high dynamic response speed. It supports multiple communication methods, including standard fully isolated RS485 communication modules, with RS422/RS485 optional. The driver integrates position control, speed control, and torque control into one, allowing dynamic switching between control modes for more flexible use. It provides protections and abnormal displays for overspeed, overcurrent, overload, overheating, main power overvoltage and undervoltage, encoder anomalies, communication errors, and PID feedback signal anomalies, making the control process clear at a glance. The motor is a three-phase permanent magnet synchronous servo motor with three times overload capacity, a rated speed of 2500 RPM, and an encoder resolution of 2500 lines.

Mechanical Parameters:

Mechanical transmission reduction ratio 1:3

Rubber roller diameter: 66mm

Accuracy requirements: The bag length accuracy is less than 0.5mm. The servo motor encoder pulse count is 2500P/R, and after quadruple frequency conversion, the resolution accuracy reaches 10000p/r, that is, v_servo=360°/10000=0.036°. The motor output to the feeding roller has a reduction ratio of 3:1, so the actual detection accuracy is: v_roller=360°/(10000×3)=0.012°, corresponding to the bag length resolution accuracy of: vl_roller=πD×(0.012°/360°)=207.24×0.000033=0.006839mm.

Therefore, its own error is far less than 0.5mm. The real cause of significant positioning error is due to the servo motor's start and stop not being smooth enough, causing jitter when stopping. Hence, it is necessary to adjust the appropriate speed loop, position loop gains, and acceleration/deceleration time according to the servo motor's start and stop speed. The debugging process is as follows:

(a) Set the position loop gain initially at a low value, then gradually increase the speed loop gain to the maximum value without causing abnormal noise or vibration.

(b) Gradually reduce the speed loop gain while increasing the position loop gain. Under the premise of no overshoot or vibration in the entire response, set the position loop gain to the maximum.

(c) The speed loop integral time constant depends on the length of the positioning time. Under the premise of no mechanical system vibration, try to minimize this value.

(d) Then fine-tune the position loop gain, speed loop gain, and integral time constant to find the optimal values.

(e) Appropriately adjust the position command first-order filter time constant.

5. Summary

This heat sealing and cutting bag machine is transformed based on traditional old equipment using the Likchuan servo control system. It features improved efficiency; reduced energy consumption; increased yield; enhanced sealing and cutting accuracy; convenient and quick debugging; smooth operation; simplified mechanical structure, and other characteristics. It has higher technical content and better cost performance, creating more benefits for enterprises.

WeChat

WeChat