Stepper Servo · 17 Years of Expertise

Application

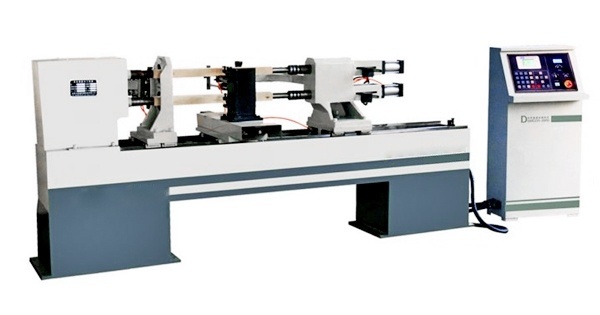

Application of Servo Communication in CNC Woodworking Lathe

With the improvement of people's consumption levels, the demand for wooden stairs and dining tables is also rapidly increasing. Against this backdrop, the manufacturing of wooden stair handrails and dining table legs has become a bottleneck in the furniture industry, leading to the emergence of fully automatic CNC woodworking lathes.

1. Features of CNC woodworking lathe:

1. The operating system features a simple and user-friendly Chinese interface, making operation easy and convenient.

2. High processing accuracy with stable processing quality. The surface processing quality of wood is better than that of ordinary woodworking lathes, greatly reducing subsequent sanding work and improving work efficiency.

3. Equipped with a four-position electric tool holder with automatic tool changing.

4. When changing processed parts, generally only the CNC program needs to be modified, saving production preparation time.

5. The machine tool itself has high precision and strong rigidity.

The CNC woodworking lathe features two-axis linkage and semi-closed loop control. It has a high-rigidity structural design and vibration absorption to ensure high-precision cutting. The servo drivers and motors controlling the feed axes X and Z require high dynamic response characteristics and precise positioning accuracy, enabling the tool post to move quickly, stably, and with high positioning accuracy.

For the machine tool spindle, it must be a high-speed, high-rigidity spindle with fast start-stop characteristics, designed for high efficiency and low noise. This ensures high processing efficiency and precision of parts, with high speed also meaning high production efficiency.

2. System Design:

CNC Lathe System Architecture

(1) CNC Control System

(2) Spindle System: Spindle Motor

(3) X-axis Drive System: 750W set

(4) Y-axis Drive System: 1KW set. The servo performance requirements for the feed axes X and Z mainly include high dynamic response and high positioning accuracy of the servo system. Lichuan servo, based on DSP+FPGA+IPM hardware platform, features high-speed frequency response with a speed response bandwidth of 450Hz, ranking among the top domestic servos; it has resonance suppression functions, precise tuning to eliminate vibration; control accuracy can reach 1 pulse, and the maximum input frequency can reach 500Kpps, all of which well guarantee the drive requirements of the feed axes.

3. Summary:

As an important functional component of CNC machine tools, the characteristics of the servo system have always been a key indicator affecting system processing performance. Lichuan servo has well met the requirements of the CNC industry and has made its own contributions to the domestic CNC industry.

Shenzhen Lichuan Electric Co., Ltd.

Technical Support

Engineer Peng:+86-135-3098-8140

Engineer Xie:86-159-0755-7836

Engineer Rao:86-180-2520-1553

Engineer Zuo:86-180-2901-2526

WeChat Public Account

Douyin ID

Official Website Mobile Version

Sorry,当前栏目暂无内容!

您可以查看其他栏目或返回 首页

Sorry,The current column has no content!

You can view other columns or return Home

WeChat

WeChat