Stepper Servo · 17 Years of Expertise

Product

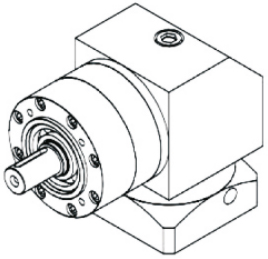

ZPLE Series Planetary Gearbox

Product Overview

The ZPLE series precision planetary gearboxes are finely crafted and offer excellent cost performance. They are compatible with all brands of stepper motors and servo motors on the market, featuring flexible design and can be customized according to motors with different mounting hole sizes. The main function of the gearbox is to reduce motor speed, amplify torque, and increase inertia. It is widely used in various motion control fields, automation equipment, and instruments.

Features

ZPLE Series Gearbox ( ZPLE060 ZPLE090 ZPLE120 ZPLE160 )

| 4 Optional Sizes | 60mm, 90mm, 120mm, 160mm |

| Rated Output Torque | 8.5N.m~680N.m | |

| Reduction Ratio Single Stage | 3, 4, 5, 7, 10 | |

| Reduction Ratio Double Stage | 12, 16, 20, 25, 28, 35, 40, 50, 70, 100 | |

| Reduction Ratio Triple Stage | 80, 100, 125, 140, 175, 200, 250, 350, 400, 500, 700, 1000 | |

| Backlash Single Stage | Precision Backlash <3 arc-min Standard Backlash <8 arc-min | |

| Backlash Double Stage | Precision Backlash <5 arc-min Standard Backlash <10 arc-min | |

| Backlash Triple Stage | Precision Backlash <8 arc-min Standard Backlash <12 arc-min |

ZPLE060 Standard Precision Planetary Gearbox

Stages | Single Stage (Including ratios 3, 4, 5, 7, 10) | Double Stage (Including ratios 12, 16, 20, 25, 28, 35, 40, 50, 70, 100) | Triple Stage (Including ratios 80, 100, 125, 140, 175, 200, 250, 350, 400, 500, 700, 1000) | ||||||

| A | B | C | A | B | C | A | B | C |

Length (mm) | 46.0 | 143.0 | 66.0 | 62.0 | 159.0 | 66.0 | 78.0 | 175.0 | 66.0 |

No-load Torque (N.m) | Approx. 0.6 | Approx. 0.3 | Approx. 0.3 | ||||||

Full Load Efficiency (%) | 95 | 93 | 90 | ||||||

Backlash (arcmin) | Precision Backlash <4 | Standard Backlash <10 | Precision Backlash <6 | Standard Backlash <13 | Precision Backlash <8 | Standard Backlash <16 | |||

Noise (dB) | ≤58 | ≤58 | ≤58 | ||||||

Weight (Kg) | 2.2 | 2.5 | 2.8 | ||||||

Rotation Direction | Input and output opposite directions | ||||||||

| For parameters not listed, please refer to PLE060 (including rated input speed / maximum input speed / maximum radial force / maximum axial force / average life / torsional rigidity / lubricating oil / protection level / installation method / reduction ratio / rated output torque / maximum output torque / moment of inertia) | |||||||||

Lichuan Planetary Gearbox Features

1. Cylindrical housing, aesthetically pleasing appearance;

2. Sealed design, compact structure;

3. High precision, good rigidity, large load capacity;

4. Small size, high efficiency, long life, low noise;

5. Convenient output end face connection installation, precise positioning;

6. Suitable for reduction transmission of AC servo motors, DC servo motors, and stepper motors.

Application Range of Planetary Gearbox

Mainly used in aerospace, CNC machine tools, cutting and welding equipment, textile and dyeing machinery, packaging machinery, food machinery, medical machinery, ships, radar, data communication systems, robots, robotic arms, composite material equipment, precision testing instruments, testing machines, plastic machinery, glass machinery, coal mining machinery, lifting machinery, metallurgical machinery, construction machinery and other industries.

Lubrication for Planetary Servo Dedicated Gearbox

1. The gearbox is sealed design, no oil change required;

2. The oil is semi-solid high-grade synthetic oil;

3. Ambient operating temperature: 0℃~+40℃

4. Maximum allowable temperature of the gearbox body below 85℃;

Note: For working environments below 0℃, please specify clearly before ordering.

Installation Sequence of Lichuan Planetary Gearbox and Servo Motor

1. Insert the servo motor shaft into the gearbox input shaft;

2. Tighten the screws (connection between servo and gearbox);

3. Evenly tighten the screws on both left and right sides with a screwdriver;

4. Tighten the torque wrenches on both sides;

5. Insert the protective layer plug into the screw hole of the reducer.

Category

Model

Format

Download

Shenzhen Lichuan Electric Co., Ltd.

Technical Support

Engineer Peng:+86-135-3098-8140

Engineer Xie:86-159-0755-7836

Engineer Rao:86-180-2520-1553

Engineer Zuo:86-180-2901-2526

WeChat Public Account

Douyin ID

Official Website Mobile Version

English website: https://www.lichuanservomotor.com/

Sorry,当前栏目暂无内容!

您可以查看其他栏目或返回 首页

Sorry,The current column has no content!

You can view other columns or return Home

WeChat

WeChat