Stepper Servo · 17 Years of Expertise

News

12

2021

-

11

"Made in China 2025" Strategy: How Can China's Manufacturing Industry Overcome Its Difficulties?

"Made in China has multiple advantages such as a vast inland development hinterland, complete industrial supporting conditions, a huge consumer market support, and hardworking manufacturers. Made in China can trade space for time, allowing it to catch its breath and continue to develop," said Liu Chengyuan, a management expert and blogger for World Manager.

"Made in China has multiple advantages such as a vast inland development hinterland, complete industrial supporting conditions, a huge consumer market, and hardworking manufacturers. Made in China can trade space for time, allowing it to catch its breath and continue developing," said Liu Chengyuan, a world management expert and blogger.

However, it now appears that the shortage of manufacturing talent, rising production costs, and insufficient domestic demand have led to a period of weakness. These competitive advantages have not been fully utilized, and the prospects for Made in China are not optimistic. China's huge trade surplus with the US and Europe has led to rising trade protectionism in those regions, continuous anti-dumping measures against China, and increasing trade barriers, all of which are the challenges faced by "Made in China."

India has conditions similar to China, with a huge potential consumer market and abundant, cheap labor. A large agricultural workforce needs to shift to the secondary and tertiary industries, requiring vigorous development of manufacturing. India has the potential to challenge China's position as the world's manufacturing center.

Unlike China's labor-intensive and capital-intensive manufacturing development model, India is taking a path toward the rise of high-end, knowledge-intensive manufacturing, fully leveraging the "spillover effect" of the high-tech industry, which will bring a huge impact to China's manufacturing industry.

Foxconn has built factories in India to produce Xiaomi and Apple phones, and after domestic phone manufacturers such as Huawei, Lenovo, Xiaomi, vivo, and Coolpad entered India, a batch of Chinese phone manufacturers followed suit and began setting up manufacturing centers in India.

Where should Made in China go? In this era of coexistence of competition and cooperation, we have no choice but to learn from them.

1. Make products carry as much high-tech content and innovation capability as possible. Everyone knows this is the most prominent core competitiveness of "Made in America."

The biggest feature of its innovation system is that enterprises, as the main body of innovation, can be fully utilized, allowing the market to regulate cooperation between enterprises, making their innovation capabilities more fully utilized and products more technologically advanced.

2. Focus on practical performance evaluation, supporting the entire enterprise through individual heroism and management innovation. Microsoft founder Bill Gates, investment guru Warren Buffett, and automotive tycoon Henry Ford all supported their industries with their own efforts.

3. Emphasize intellectual property protection while encouraging technological innovation in small and medium-sized enterprises. US laws allow SMEs to co-fund research with the government and obtain patents, encourage registering intellectual property to SMEs, require national laboratories to promote the transfer of results to enterprises, and allocate some capital to support SME scientific research. The stock market has also established NASDAQ, providing direct financing specifically for small and medium-sized technology enterprises.

4. Concentrate R&D investment in high-tech fields to ensure innovative development of high technology. The US invests a large amount of funds annually in high-tech fields, which is still lacking in our country.

In the 1970s and 1980s, "Made in Germany" was once sneered at by the then "world factory" Britain, but today Germany has created countless well-known brands and proposed the "Industry 4.0 Plan" as early as two years ago.

1. It has its unique technician system. Former German President Herzog once said, "To maintain economic competitiveness, Germany needs not more PhDs, but more technicians." Although somewhat exaggerated, it reveals the special importance of highly skilled talents to Germany's real economy.

2. German technology is specifically reflected in research and development, concentrating strengths to deeply study limited fields, thereby producing extraordinary originality and uniqueness. The technician system and originality in R&D are two methods commonly used by German enterprises and are among the fundamental reasons for Germany's sustained economic strength.

3. Everything must be done rigorously. The rigorous character of the German people has shaped today's Germany. German enterprises attach great importance to product quality; a strong quality awareness has become the core of corporate culture, deeply rooted in employees' minds. Both Volkswagen and Siemens require employees to establish strict quality awareness and promote a quality concept of continuous improvement within the company.

4. Send technicians to Germany for training, allowing them to strengthen their skills while enjoying the influence of German national culture, cultivating a group of people with high quality awareness and high qualifications.

1. Emphasize the collective and teamwork. This is caused by the homogeneity of the Japanese people. Japanese enterprises emphasize teamwork, which can bring the entire enterprise into a new development stage in a short time, improving internal tacit understanding and achieving consistency, thus maximizing organizational efficiency.

Every employee may participate in various work processes within the enterprise, integrating everyone into the organization to form overall coordination and cooperation! They value team and organizational success and emphasize sacrificing the individual for the overall organization.

2. Emphasize employee training and internal promotion. In Japanese enterprises, there are generally opportunities for overseas training to improve employees' skills and overall quality. In terms of recruitment, internal adjustments are prioritized to meet job requirements, saving unnecessary time and enabling work to start quickly.

Although the pressure is great, the direction of the path is still forward. Currently and in the future, we must firmly grasp the historic opportunity brought by the new round of technological and industrial revolution, implement policies and measures more favorable to the development of the real economy, and reshape the comparative advantage of "Made in China" in the new environment.

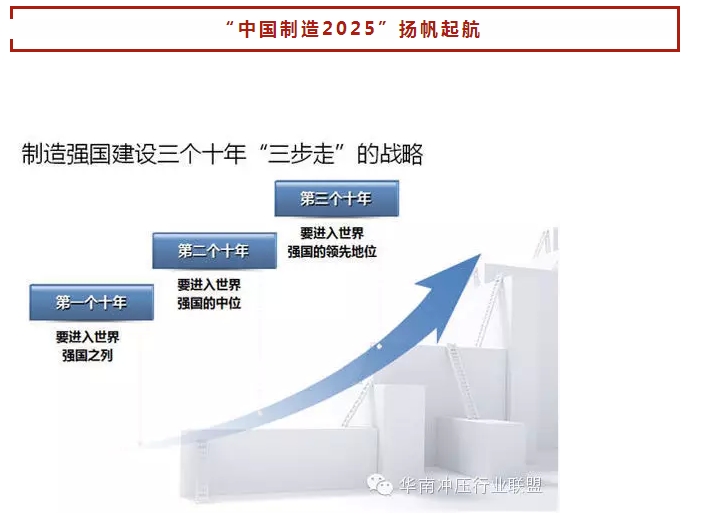

And the proposal of the "Made in China 2025" strategy further plans the development path for China's manufacturing industry over the next decade, pointing out the direction. It adheres to the basic policy of "innovation-driven, quality first, green development, structural optimization, and talent-oriented," and the basic principles of "market-led, government-guided, focusing on the present and looking to the long term, overall promotion with key breakthroughs, independent development, and open cooperation." Through a "three-step" approach, it aims to build China into a manufacturing powerhouse.

Guangdong Lean Management Research Institute

Related News

Shenzhen Lichuan Electric Co., Ltd.

Technical Support

Engineer Peng:+86-135-3098-8140

Engineer Xie:86-159-0755-7836

Engineer Rao:86-180-2520-1553

Engineer Zuo:86-180-2901-2526

WeChat Public Account

Douyin ID

Official Website Mobile Version

Sorry,当前栏目暂无内容!

您可以查看其他栏目或返回 首页

Sorry,The current column has no content!

You can view other columns or return Home

WeChat

WeChat